Precision starts with pattern and core technology.

Every investment casting begins with a wax pattern and a ceramic core, where small and/or complex internal features are required. Together, these elements define the geometry and surface quality of the final casting. For advanced airfoils and structural castings alike, accuracy at this stage is essential to the success of the final product. CPP’s in-house capabilities in both wax and core technologies ensure consistency, repeatability, and the capacity to support highly complex scale production.

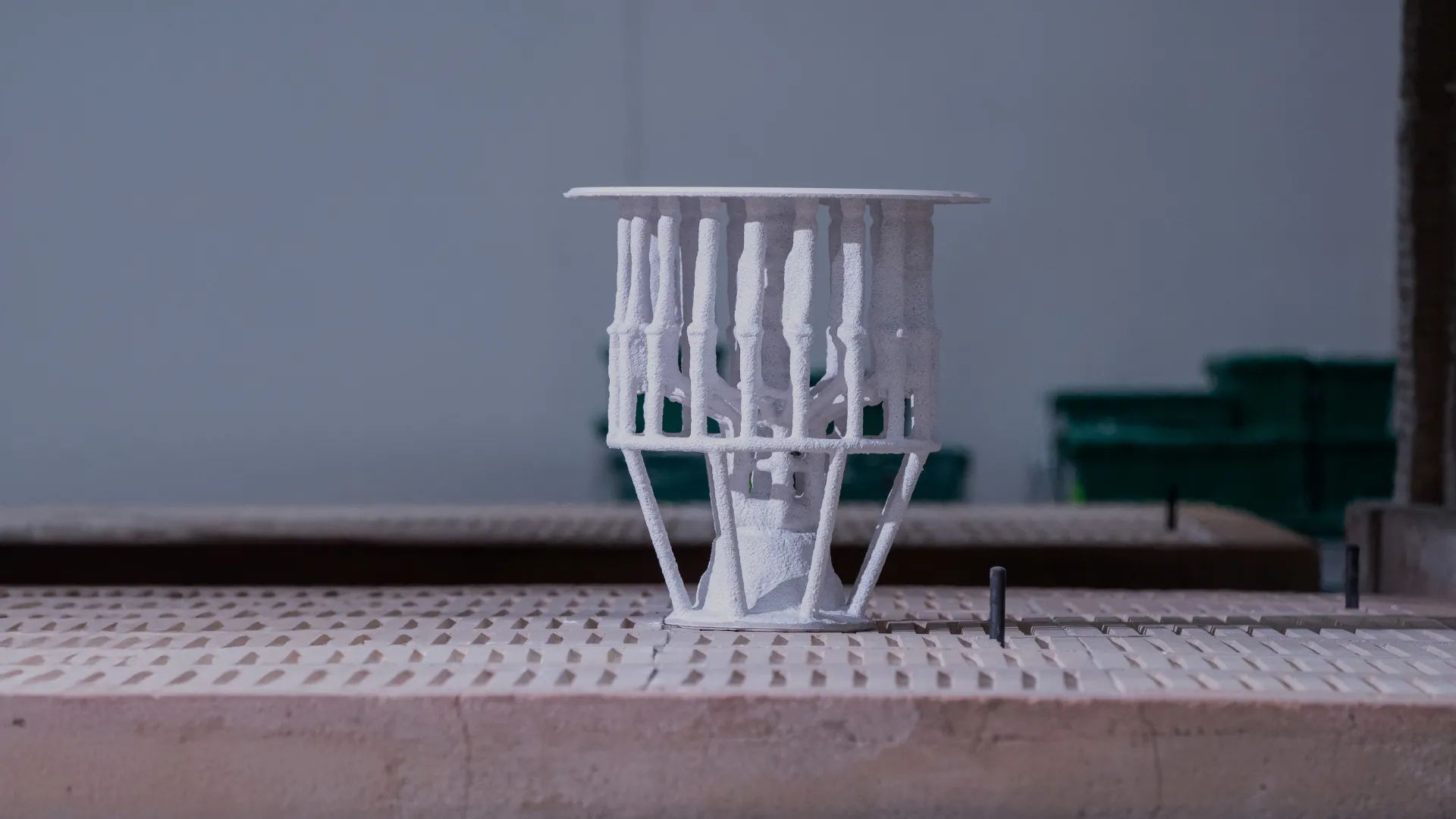

Advanced core technology with Poly6.

Born from MIT’s Langer Lab and acquired by CPP in 2019, Poly6 brings next-generation additive manufacturing capability to ceramic core production for airfoil castings. Using its proprietary process, Poly6 produces highly complex multi-wall cores with intricate internal features tailored for advanced airfoil cooling. These cores form the critical internal passages that allow turbine blades and vanes to operate at temperatures above their melting point, which enables high thermal efficiency, reduced fuel burn, and longer part life. With its operations in Massachusetts and Ohio, Poly6 supports CPP’s most advanced airfoil casting capabilities.

High-precision wax patterns with AirPower Dynamics.

The dimensional accuracy and repeatability of every investment casting depends on the precision of the wax pattern, where even minor variation can affect dimensions and yield. In 2024, CPP acquired AirPower Dynamics (APD), a best-in-class wax pattern manufacturer in Mentor, Ohio. APD brings deep expertise, process rigor, and decades of experience in supplying complex geometry tight-tolerance patterns and assemblies and ensures the capacity required for CPP’s expanding airfoil operations.

Help us shape the future.

Every CPP career comes with incredible growth potential and the satisfaction of knowing that you’re helping shape a better tomorrow for everyone—starting with yourself.