Advancing efficiency, sustainability, and performance in aviation.

Commercial aviation continues to evolve in response to growing demand for lower fuel burn, reduced emissions, and quieter, more efficient aircraft. These goals are driving the development of new engine architectures, lighter-weight airframes, and engine components capable of withstanding the higher operating temperatures and/or stresses needed to improve both thrust and operating efficiency. At the same time, rising global passenger demand has boosted the OEM backlog and accelerated aircraft production rates—requiring all aerospace suppliers to deliver not only advanced technologies but also scalable, repeatable manufacturing solutions. As a result, OEMs increasingly rely on a small community of casting suppliers with both the technical expertise and production capacity to support the next generation of flight.

How CPP supports the commercial aerospace industry.

CPP helps each of the world’s leading OEMs meet their challenges through broad capabilities and deep process expertise across both engine and airframe systems. We are among the few suppliers capable of reliably providing production quantities of the most advanced hot-section DS and SX airfoils. Our expertise spans investment and sand structural castings and a broad range of alloys—enabling production of some of the largest and most complex components used on today’s aircraft. We have earned the trust of our OEM partners by:

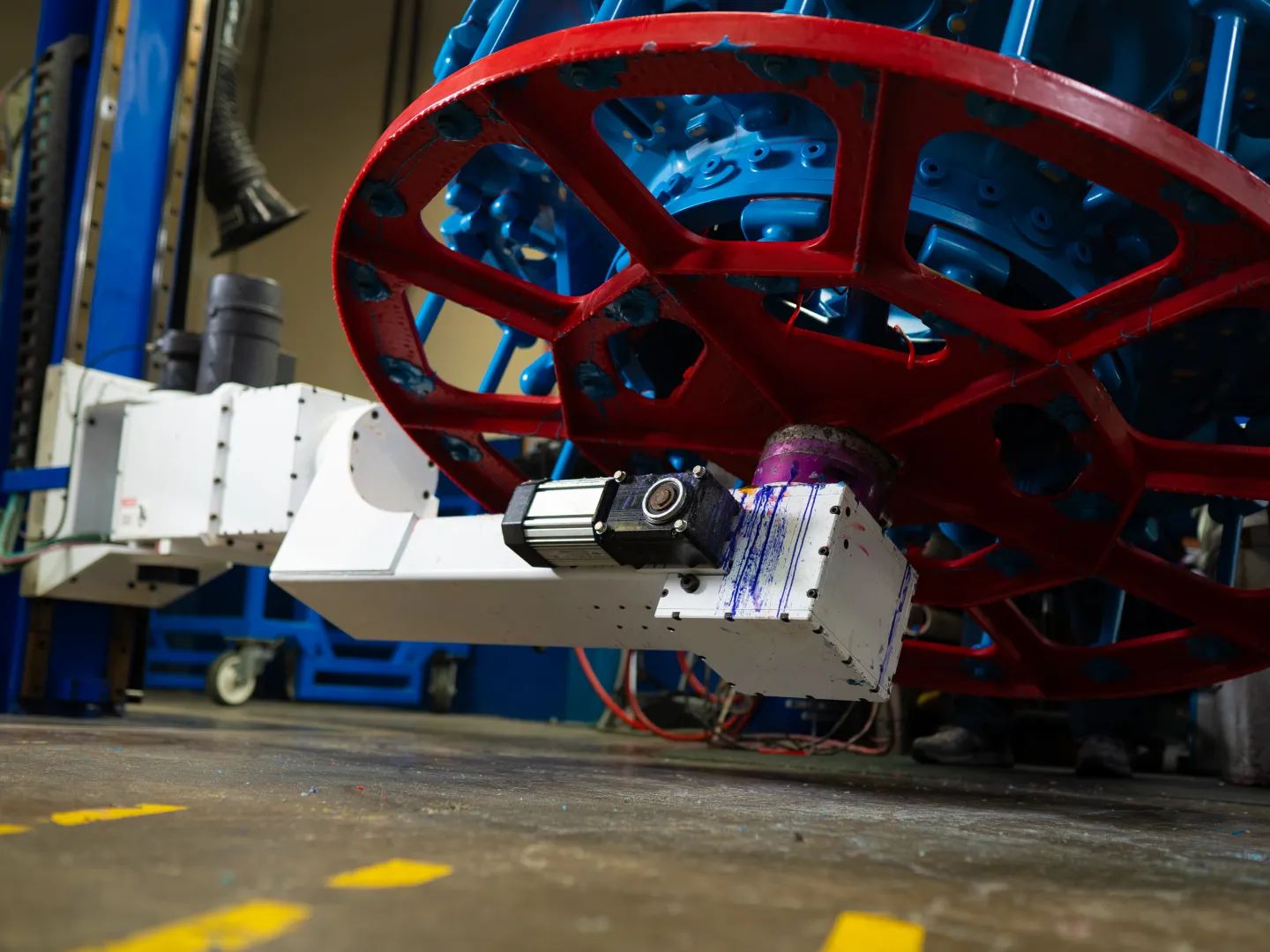

- Continuing to advance technology. CPP’s Poly6 applies next-generation additive manufacturing to produce the intricate multi-wall ceramic cores that form cooling passages in the most advanced turbine airfoils.

- Investing to support growth. CPP has established and qualified new airfoil capacity in both Ohio and Poland.

- Expanding melt capabilities. In New York and Oregon, CPP’s new installations work to secure the alloy supply chain and support our customers’ production demands for reliable, high-performance castings.

A comprehensive portfolio across engines and airframes.

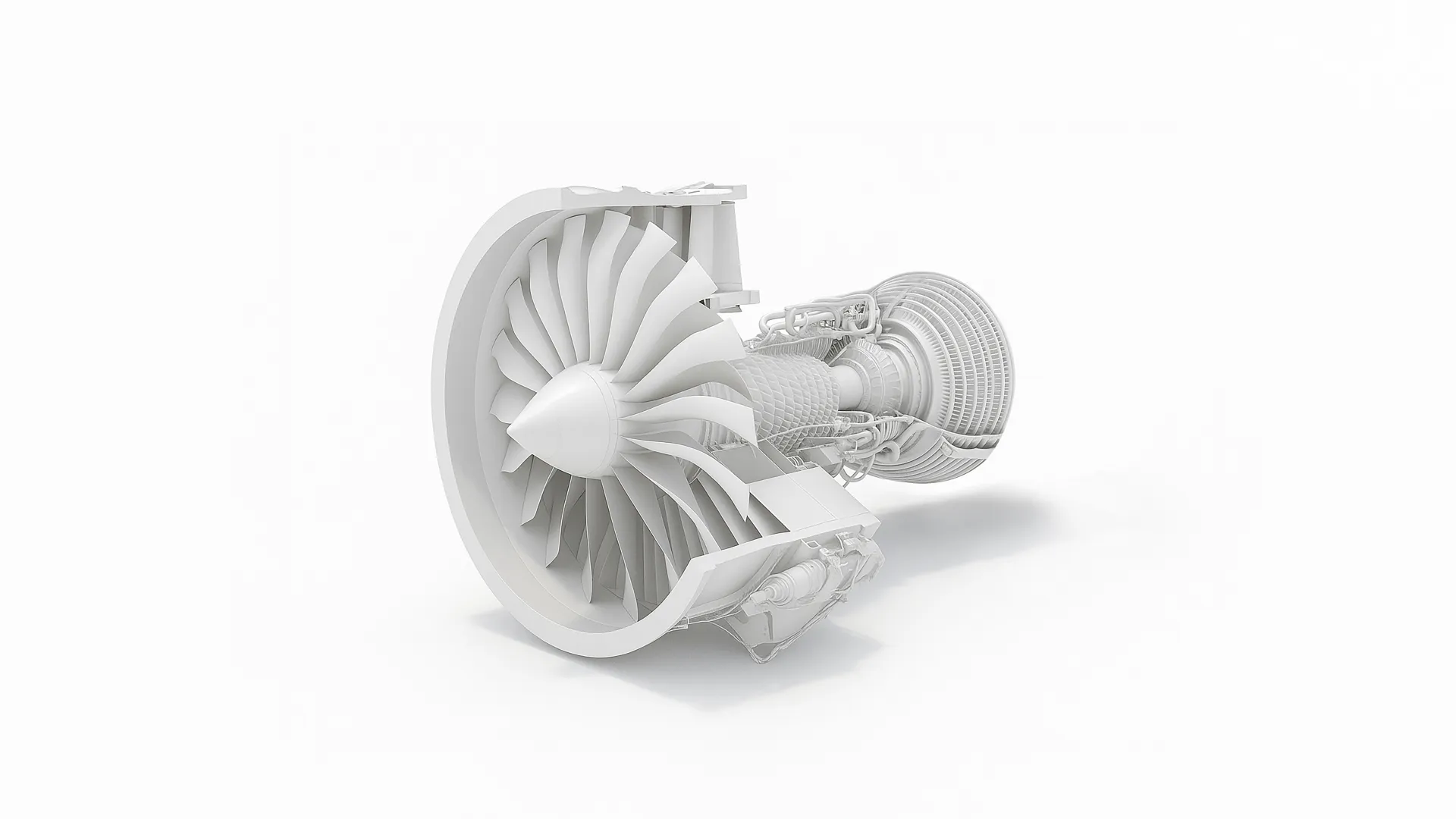

CPP produces castings for nearly every major commercial aircraft program in production. Our components span the full engine and airframe—from hot-section turbine blades, vanes, and fairings to gearboxes, housings, hubs, frames, flaps, fittings, valve bodies, and more. We cast a wide range of materials—including titanium, steel, aluminum, magnesium, and nickel- and cobalt-based superalloys—allowing us to support both propulsion and structural systems with the material integrity and process control required for flight-critical performance. As aircraft technologies advance, CPP’s casting portfolio continues to evolve to meet the complexity of next-generation commercial platforms.

Product overview.

Help us shape the future.

Every CPP career comes with incredible growth potential and the satisfaction of knowing that you’re helping shape a better tomorrow for everyone—starting with yourself.