About

CPP Syracuse specializes in casting a diverse range of components for both airframes and engines using a wide variety of nickel- and cobalt-based superalloys. Our advanced manufacturing capabilities allow us to produce highly complex castings, including structural non-rotating parts as well as rotating parts within the hot section of the engine. Our current engine casting portfolio includes critical components such as bearing housings, exhaust cases, combustor components, TCF fairings, near flow-path seals, and LP turbine blades, shrouds, and vanes.

Alloys

- Nickel Superalloys

- Cobalt Superalloys

- Equiaxed

Steel

Max Pour Weights: 530 lbs

Max Part Size: 31"x30"x12"

Products

- Turbine Shrouds, Blades, Fairings and Vanes

- Turbine Rear Frame

- Struts and Mounts

- Near Flow-Path Seals

Certificates

NADCAP

- Nondestructive Testing

- Welding

- Materials Laboratories

PRI

- ISO 9001:2015

- AS9100D

- EN9100:2016

- JISQ9100:2016

Contact

901 E Genesee St

Chittenango, NY 13037

Phone: (315) 687-0014

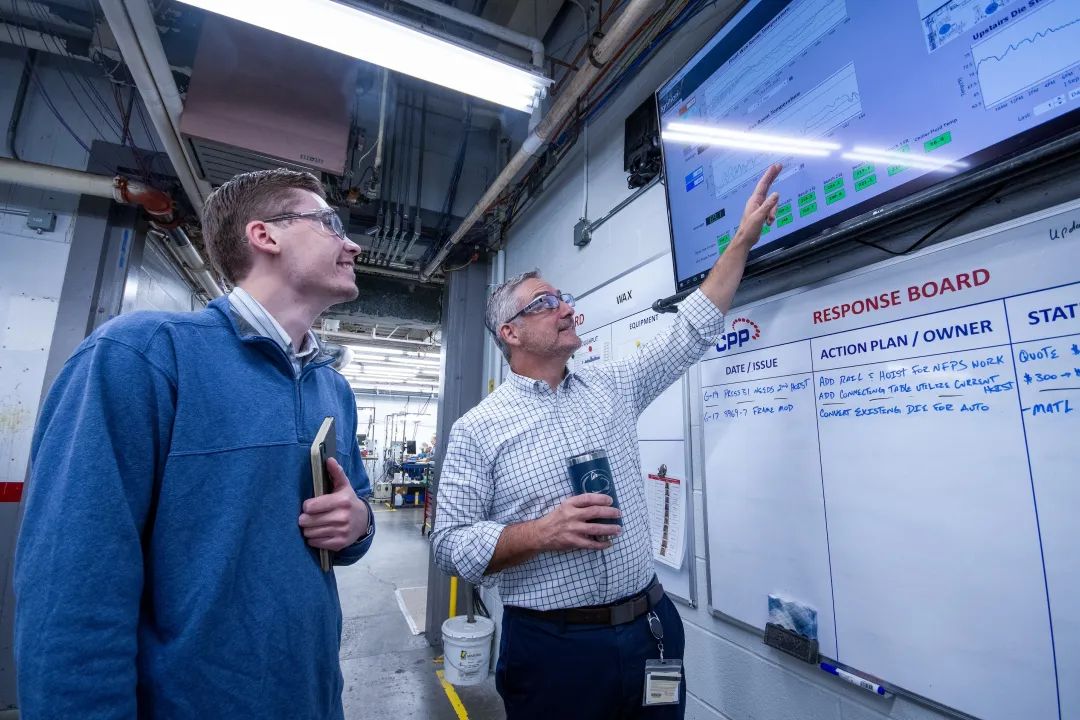

People + Culture

We foster a culture of safety, innovation, and continuous improvement. We are committed to building a talented, dedicated team by encouraging open communication, rewarding initiative, and continuously expanding our capabilities. At CPP Syracuse, you will find a results-driven culture and a collaborative atmosphere that offers opportunities for career growth and professional development.

Help us shape the future.

Every CPP career comes with incredible growth potential and the satisfaction of knowing that you’re helping shape a better tomorrow for everyone—starting with yourself.